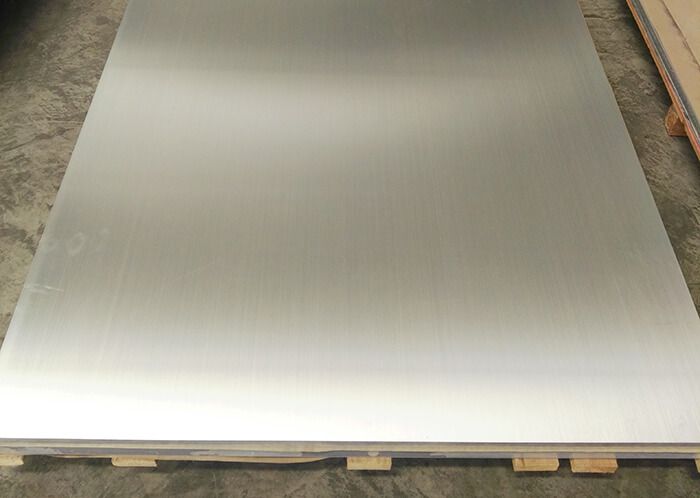

6061 aluminum sheet is a precipitation-hardened aluminum alloy containing magnesium and silicon as its primary alloying elements, developed in 1935. It has good mechanical properties, has good weldability, and is very commonly extruded (second only to 6063).

Aluminum 6061 sheet is one of the common general-purpose aluminum alloys. Its main tempers include 6061-O (annealed), 6061-T6 (solution and artificially aged), and 6061-T651 (solution, stress-relieved tensile and artificially aged).

Construction of aircraft structures such as wings and fuselages. The 2024 alloy is slightly stronger, but 6061 is easier to machine and maintains corrosion resistance even if the surface is worn, unlike 2024, which is often used with a thin coating to improve corrosion resistance.

Yacht building, including small multi-purpose boats

Car parts

Flashlight

Aluminum cans for packaging food and beverages

Bicycle frames and components

Parts of remote control model aircraft, especially helicopter rotor parts

Fire rescue ladder

6061 aluminum alloy s highly weldable, for example using Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG) welding. Typically, after welding, the properties near the weld are those of 6061-T4, with a strength loss of approximately 40%.

The material can be reheat treated to restore the whole piece to a near-T6 temper. After welding, the material can age naturally and regain some of its strength. Most strength returns within the first few days to weeks.

6063 aluminum plate is an aluminum-magnesium-silicon alloy aluminum plate, containing manganese and phosphorus elements, as well as a small amount of copper and iron elements.

6063 aluminum alloy is a representative product of high-hardness alloys, which is the core reason why it is often seen in various mechanical parts, precision machining and abrasive manufacturing.

The yield strength of 6063-T1 aluminum plate is 95Mpa and the hardness is: 42HB.

The yield strength of 6063-T5 aluminum sheet is 175Mpa and the hardness is: 60HB.

The yield strength of 6063 T6 aluminium sheet is 175Mpa and the hardness is: 73HB.

The yield strength of 6063-T832 aluminum alloy plate is 240Mpa, the hardness is: 95HB.

Original Source:https://www.aircraftaluminium.com/a/what-are-properties-and-uses-of-aluminum-6061-6063-sheet.html

Tags: 6061 aluminum sheet ,

Contact Us