Why is aluminum used for aircraft bodies? Aircraft aluminum alloys have many excellent properties such as high toughness, corrosion resistance and fatigue resistance. Since the early 20th century, they have been widely used in the aviation field as the fuselage skin, beams, stringers,etc. According to the difference in the service performance and use of the aircraft, the amount and specifications of aluminum alloys on the aircraft are also quite different.

7xxx aluminum alloy is another commonly used alloy with a wide variety. It contains zinc and magnesium. The most common aluminum alloy with the best strength is 7075 aircraft aluminum. How about aluminum alloy 7075 properties?

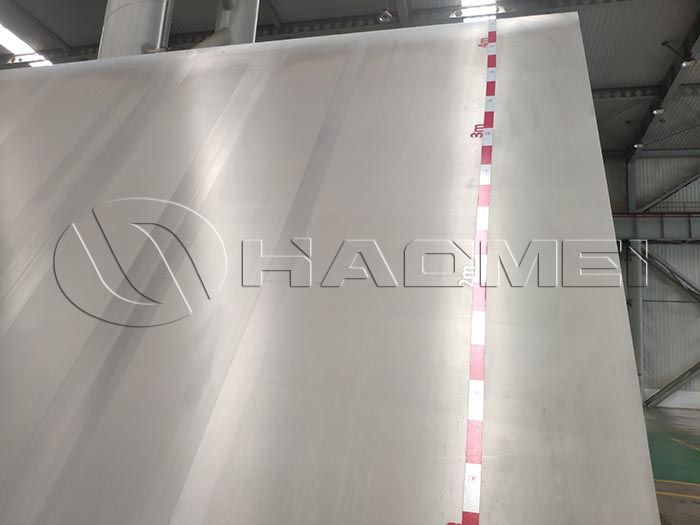

7075 aluminum alloy is a cold-worked wrought alloy, one of the strongest commercially available alloys. It has normal corrosion resistance, good mechanical properties and anodic reaction. The finer grains result in better deep drilling performance, enhanced tool wear resistance and distinctive thread rolling.

7075 mainly contains zinc element, which is an aluminum-magnesium-zinc-copper alloy and a heat-treatable alloy. It is a super-hard aluminum alloy and has good wear resistance. The 7075 aluminum plate is stress relieved and will not deform or warp after processing. All super-large and super-thick 7075 aluminum plates are ultrasonically detected, which can ensure no blisters and impurities. 7075 aluminum plate has high thermal conductivity, which can shorten the forming time and improve work efficiency.

After solution treatment, it has good plasticity, good heat treatment strengthening effect, good strength below 150 degrees, and particularly good low temperature strength, poor welding performance, and tendency to stress corrosion cracking.

7075 aluminum plate is generally added with a small amount of copper, chromium and other alloying element. Among this series, the 7075-T651 aluminum alloy is known as the best product in aluminum alloys. This alloy also has good mechanical properties and anodic reaction.

LLOY | TEMPER | DIRECTION | THICKNESS(MM) | TENSILE STRENGTH(MM) RM(MPA) | YIELD STRENGTH RP0.2(MPA) | BREAKING ELONGATION A50% | STANDARD |

7075 Thick Plate | T651 | LT | 6-260 | 570-590 | 495-515 | 10-13.5 | GB/T3380 |

T7651 | LT | 6-102 | 550-560 | 480-490 | 10.5-12.5 | AMS4045K | |

T7351 | LT | 6-102 | 500-520 | 420-435 | 10-12.5 | AMS4078 | |

7075 Thin Plate | T6 | - | 0.5-3.5 | 550-570 | 480-500 | 11-15 | GB/T3880 EN485 ASTM B209 |

Original Source:https://www.aircraftaluminium.com/a/why-is-aluminum-used-for-aircraft-bodies.html

Tags: 7075 aircraft aluminum ,

Contact Us