The extreme operating conditions of aviation (temperature swings of -55°C to 120°C, 9G overloads, salt spray corrosion, etc.) place stringent demands on materials. This certification system, through standardized testing and process control, ensures the reliability of aluminum throughout the entire production and application chain.

Unlike ordinary industrial aluminum, aircraft aluminum must pass three key hurdles: material standard certification, process capability certification, and quality management system certification. These three criteria together constitute the core entry threshold for this industry.

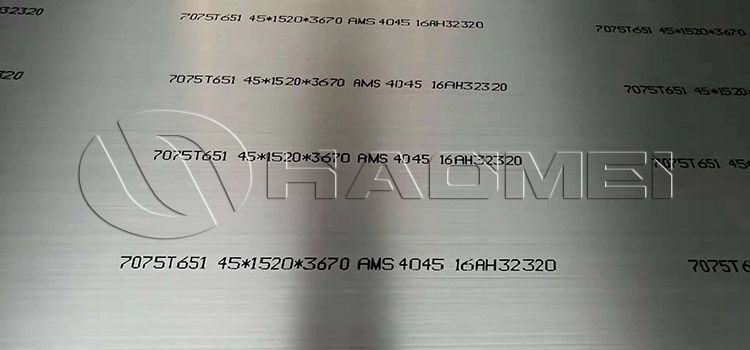

AMS (Aerospace Material Specification): Developed by the Society of Automotive Engineers (SAE), it is the most authoritative "performance identification card" for aviation aluminum. For example, the widely used alloy 7075 must comply with the AMS-QQ-A-200/11 standard, which specifies tensile strength ≥ 524 MPa, yield strength ≥ 455 MPa, and impurity iron content ≤ 0.5% and silicon content ≤ 0.4%. Furthermore, military applications must meet the MIL-A-8190D standard, which includes even more stringent testing for fatigue life and fracture toughness.

ASTM (American Society for Testing and Materials): Complementing AMS, ASTM B209 specifies dimensional tolerances and mechanical property test methods for aircraft aluminum alloy plate. 7075 aluminum plate must pass this standard's tensile test, hardness test (Brinell hardness ≥ 150HB), and grain size test (average grain size ≥ 7).

ISO/EN standards: Mainstream standards in the European market. For example, ISO 209.1 specifies the chemical composition of aluminum alloys, while EN 485.2 defines the performance requirements for aircraft aluminum extrusions. These standards are generally consistent with AMS, but the testing methods differ slightly.

The performance of aircraft aluminum alloys is highly dependent on processes such as heat treatment and nondestructive testing. Therefore, NADCAP (Aerospace and Defense Contractors Accreditation Program) certification is crucial. For heat-treatable alloys like 7075, matweb 7075 t6 must pass a NADCAP audit.

This audit covers heating temperature deviation (within ±5°C), holding time accuracy, and cooling rate monitoring. Furthermore, non-destructive testing (NDT) of raw materials, such as ultrasonic testing (UT) and radiographic testing (RT), must also be included in the NADCAP certification to ensure the absence of defects such as internal cracks and pores.

All aviation aluminum suppliers must be certified to AS9100D. This system enhances ISO 9001 with specialized aviation-specific requirements:

Material Traceability: 7075 aluminum must be fully traceable, from ingot batches and melting records to finished product inspection reports. Each extrusion must be uniquely identified.

Process Control: Heat treatment furnaces must be calibrated quarterly, and chemical composition analysis must be performed using a spectrometer with data retention for at least five years.

Risk Control: To address the stress corrosion susceptibility of 7075, a dedicated testing plan must be established and salt spray test data must be maintained (minimum 500 hours with no corrosion pits).

Due to its high strength (its specific strength exceeds that of mild steel), 7075 is used in aircraft load-bearing structures. Its certification requirements are precisely tailored to the application scenario:

Landing gear components: They must simultaneously meet AMS-QQ-A-200/11 (mechanical properties), NADCAP heat treatment certification (to ensure strength stability), and AS9100 traceability requirements;

Missile casings: They must additionally meet the military standard MIL-A-8190D, with enhanced impact toughness testing (impact energy ≥ 20J);

Civil aircraft structural components: In addition to basic certification, they must undergo additional airworthiness fatigue testing to ensure performance degradation of ≤10% over a 30-year service life.

Qualification Document Verification: Suppliers are required to provide AMS-compliant material lists (including complete mechanical properties and chemical composition data), NADCAP certification (validity verified via eAuditNet), and AS9100 audit reports.

Key Inspection Parameters: Randomly sample 7075 profiles and commission a third-party testing agency to re-evaluate tensile strength and hardness. Deviations must be within ±5% of the standard value.

Original Source:https://www.aircraftaluminium.com/a/what-certifications-do-aircraft-aluminum-alloys-need-to-meet.html

Tags: 7075 aluminum plate ,

Contact Us